L.B. SIDERTECH in the person of its owner Luca Briganti, in 35 years in this sector has contributed to developing the technology of impedances and also of inductances with all the best manufacturers of generators for high frequency welding as well as with the largest international groups producing electro-welded tube.

We do not limit ourselves to the supply of custom-made inductors but also to offer our pro-active consultancy to our customers.

We can suggest the best sizes and types depending on the characteristics of the pipe manufacturers' systems to optimize their production.

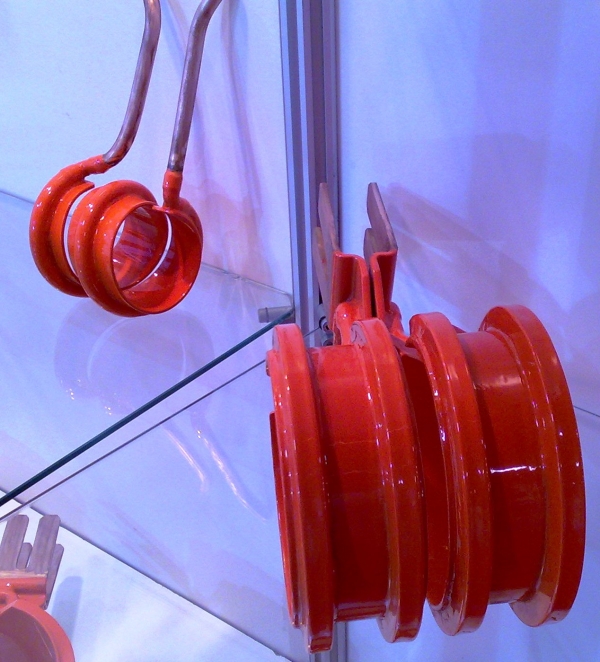

- Traditional with round section copper coils coated in PTFE Teflon

- With copper coils with an oval section with an enlarged polar footprint (instead of the brazed copper strip), insulated by electro-deposited or painted insulated with epoxy resin.

- Band with brazed cooling, also to design, for pipes of large diameter and thickness, insulated with Epoxy resin electrostatically deposited and melt in the oven.

- Special with designed internal shape

The inductors must be carefully proportioned and always together with the impeders since together they constitute the induced electromagnetic circuit which makes good and efficient induction welding possible.