Since 1967 MEC ( Metallizing Equipment Co. pvt Ltd ) is internally and also , co-operating with all most important universities and research institutes in India , developing a wide and complete range of devices for the Thermal Spraying process . Thermal Spraying is a group of coating processes in which finely divided metallic or non-metallic are deposited in a molten or semi molten condition with extremely high velocity to form a coating . Thermal Spraying process has advantage over other processes as it is cold process so it never distorts parent material ( substrate ) . Nowadays this technology allows our customers using a wide range of different coating materials , such as pure metals and their alloys as well as oxides and nitrites in any form as wires , rods or powders . Another advantage of Thermal Spraying process i to be able to control with no limitation of the job size the thickness of coating . MEC has been founded by Mr M.D. Modi ( Chairman ) since many years greatly supported by his Son Mr S.C. Modi ( Managing Director ) and thanks also to the precious co-operation of the Executive Director Mr Ankur . Today Mec is one of the most important International actor in the production of integrated systems for part preparation by Sand Blasting and Thermal Spraying coating by solving by customizing a number of technical problems . MEC has today nearly 200 people working in a family environment , with a R & D centre recognized from the department of science & industrial research of Indian government . MEC has many international patents and it is complying with ASTM Standards and almost all MEC devices carry the CE Mark ( European Inspection & Certification Co. S.A. )

WHAT THERMAL SPRAYING CAN OFFER

- CORROSION PROTECTION

- ELECTRICAL CONDUCTIVITY AND RESISTIVITY

- PART RESTORATION AND REFURBISHING

- WEAR RESISTANCE

MEC’s technologies and products are widely used in following market segments :

- Oil & gas industry

- aerospace industry

- bio-medical industry

- automotive industry

- steel mill industry

- glass industry

- textile industry

- chemical industry

- power-plants industry

- pulp & paper industry

- construction industry

- defence industry

- dredging industry

- electronic industry

- food processing industry

- hydraulic industry

- marine industry

- every day new applications born getting wider the MEC presence in new markets .

MEC offers a wide registered products such as :

- SPRAYNET = wire flame spray system

- POWDERJET = powder flame spray system

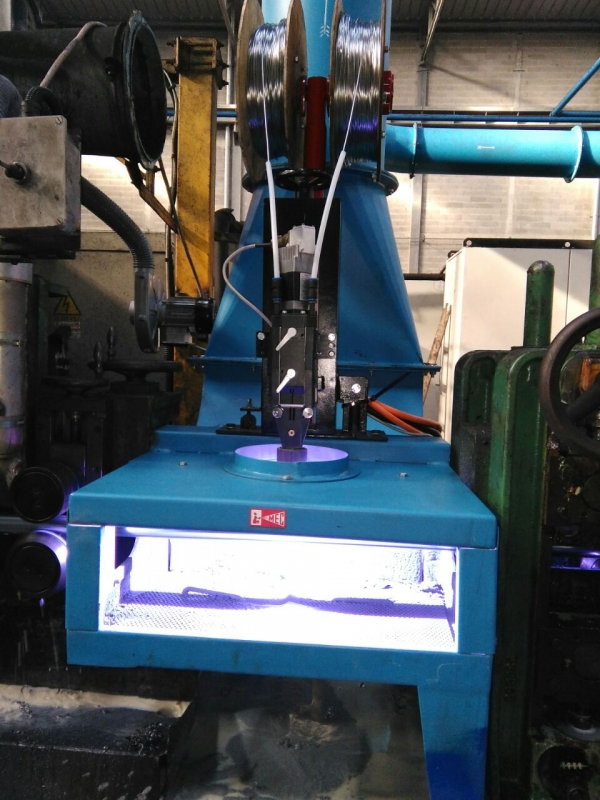

- ARCJET = arc spray system ( air & electricity )

- HIJET = HVOF ( wire ) spray system

- HIPOJET = HVOF ( powder ) spray system

- XPOJET = liquid fuel HVOF ( powder ) spray system

Quantity of different type of materials and alloys is today extremely wide more than 100 in many different conditions such as wires , rods and powders .For example wires such as : Aluminium and its alloys , Titanium and its alloys , Nickel and its alloy , Zinc and its alloy , different grades of stainless steel , Brass , Monel , Copper and many others . For example powders such as : Tungsten carbide and Chrome and just Chrome , NiAl , NiCrSiB , Stellite 6 , Lega 625 etc . Or ceramic powders such as : Zirconium Ittrio based , Chrome oxide , Alumina – Titania etc . Other materials such as abradables , such as : nickel graphite , aluminium polyester , etc.

MEC is capable to supply complete technology package by customizing customer needs which includes:

- Surface preparation unit

- Coating systems

- Acoustic chamber with dust collector

- Job rotation system

- Thermal spray robot 7 axis

- Mec’s laboratory support

- Operator & maintenance training

- Technology know-how support

An International network of MEC’s technicians and agents is available to cross technical info and support all customers for whatever kind of problem solving .

MEC has developed a complete range of high performance masking tapes specifically designed to meet the needs of the Thermal spraying industry.

These tapes ensure :

- High temperature resistance

- High mechanical resistance

- Excellent abrasion resistance ideal for grit blasting and plasma , HVOF applications .

Typical tape’s dimensions are :

width from 1/8 to 48” ( from 3,2 to 1220 mm )and standard length of 36 yds ( 33 mt approx )

Most common type of tapes are :

- Silicone coated fibreglass tapes

- Fibreglass cloth tapes

- Fibreglass tapes , double coated

- Aluminium foil tapes